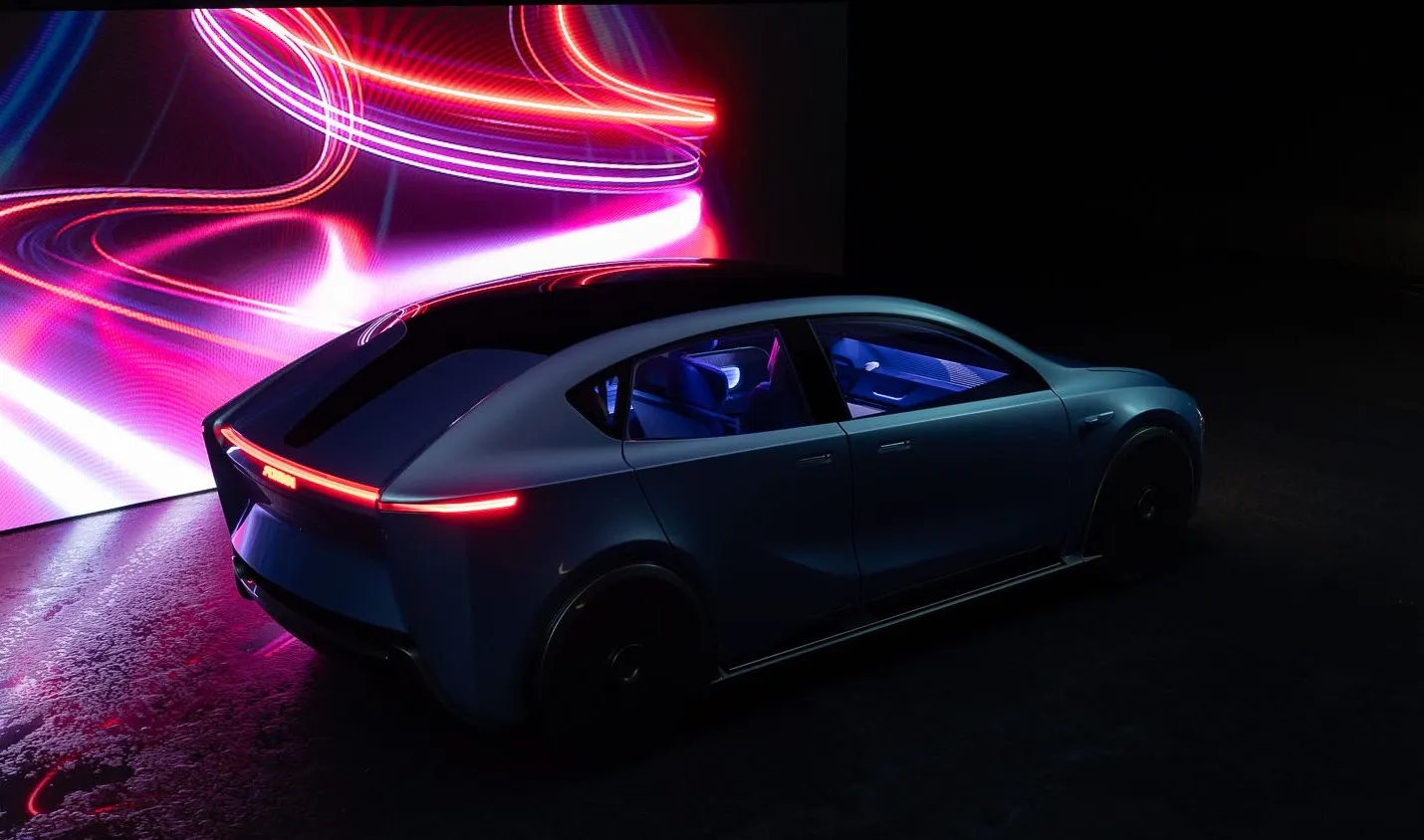

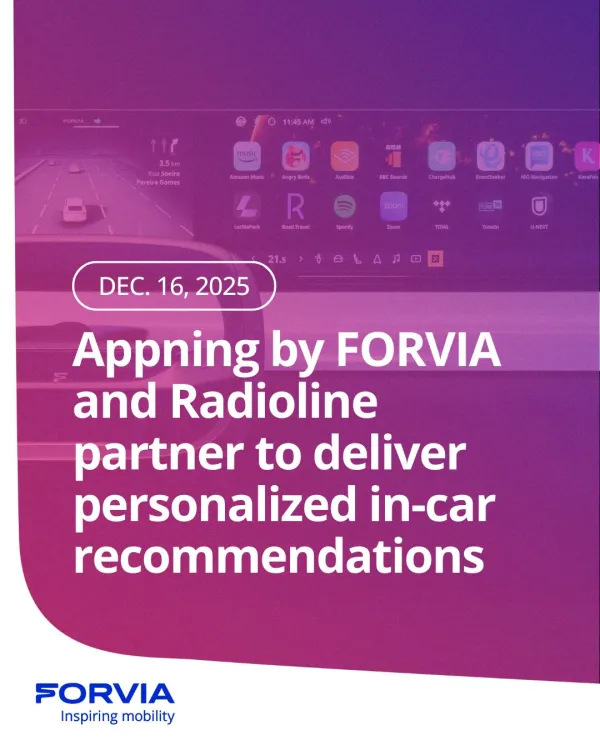

Nos technologies phares

FORVIA sur les Réseaux Sociaux

Chiffres clés

Notre engagement : prendre soin des personnes et de la planète

Bâtir un monde plus inclusif

Nous sommes convaincus que la diversité est une force. Véritable fondement de notre culture et de notre identité, elle nous permet de mieux comprendre notre environnement et de décupler nos capacités d’innovation.

Impulser un avenir durable

Nous avons défini une feuille de route nous permettant d'atteindre la neutralité carbone en 2045, feuille de route certifiée par l'organisme tiers SBTi (Science Based Targets initiative). Nous sommes également le premier groupe automobile mondial à avoir obtenu la plus haute de leurs certifications.

Mener nos activités de manière responsable

Nous nous engageons à respecter les plus hauts standards d'éthique des affaires dans tous les pays où nous opérons et promouvons une culture de l’intégrité dans nos activités.