FORVIA wins SPE Innovation Award for Microject Advanced, a lightweight injection technology for high-end automotive interiors

FORVIA has been awarded the prestigious Innovation Award from the Society of Plastics Engineers (SPE) in Bonn, Germany, on October 6th, for Microject Advanced, a breakthrough injection molding technology that redefines what's possible in lightweight, visible automotive components.

Microject Advanced stood out for its ability to deliver up to 25%-part weight reduction while achieving flawless, high-definition surfaces eliminating the need for post-processing such as painting or covering.

“This recognition underscores FORVIA’s commitment to developing sustainable technologies that help automakers reduce vehicle weight, cost, and CO₂ emissions, all while expanding design freedom for affordable interiors with a premium look,” said Stéphanie Cohen, Vice President Strategy and Innovation Marketing FORVIA Interiors.

Lightweight without compromise on performance

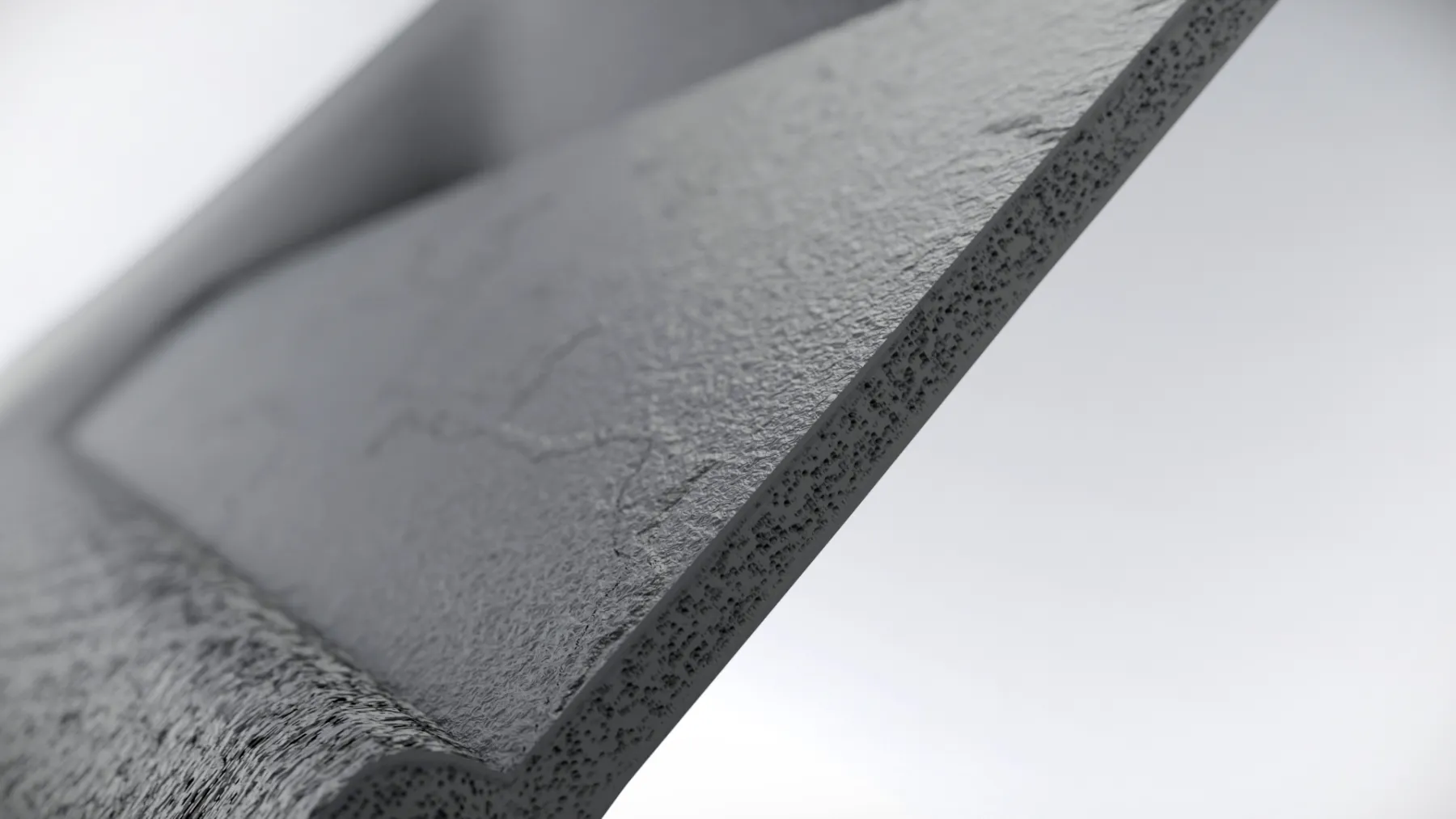

Traditionally, foamed injection molding has been limited to non-visible parts due to surface defects. Microject Advanced changes the game. Combining microcellular foaming, nature-inspired structural features, and a patented ceramic mold coating, the technology enables the production of A-class visible components that are significantly lighter yet structurally robust.

Depending on the application, Microject Advanced reduces part weight by 15–25%, and by up to 50% when replacing painted or covered components. These weight savings directly translate to lower vehicle CO₂ emissions during use, while its mono-material construction, compatible with recycled and bio-based materials, simplifies recycling at end-of-life and supports circular economy targets.

In production, the process eliminates entire steps such as additional molding for features like airbag shoot channels, or post-processing like painting, bringing up to 45%* CO₂e reduction throughout the entire lifetime. Microject Advanced offers OEMs a cost-effective and sustainable solution already in serial production with leading automotive brands.

Design and performance reimagined

Microject Advanced also unlocks new design potential for interior components. Thanks to an advanced in-mold grain transfer process the technology achieves exceptional surface definition with a wide range of textures effects such as leather, stone, textile, wood, and more, directly molded into the part.

Beyond aesthetics, the process introduces greater design freedom and functional integration. Reduced wall thickness and nature-inspired structural features, improves mechanical performance while avoiding visible defects.

This holistic approach means OEMs can deliver affordable, sustainable, and visually distinctive interiors, while also benefiting from significant weight, cost, and emissions savings.

* The reduction in CO₂ emissions was calculated based on the product's carbon footprint, in accordance with ISO 14067, by comparing the new injection process to a reference solution. The analysis followed a cradle-to-gate approach, including the materials used as well as the production and transformation stages of the part.